In-Mold Decorations: Integrating Style and Production Excellence

In-Mold Decorations: Integrating Style and Production Excellence

Blog Article

Grasping In-Mold Decorations: Methods, Trends, and Finest Practices for Ideal Results

In the world of production, the art of in-mold decorations stands as an essential aspect of item design and production. In-Mold Decorations. By delving into the approaches, trends, and best practices that underpin effective in-mold design procedures, businesses can open a world of opportunities that not just raise the visual appeal of their products however likewise enhance production effectiveness and strengthen consumer engagement.

Material Option

Material option is a crucial facet of mastering in-mold decors, as it straight influences the high quality and resilience of the final product. When selecting products for in-mold decorations, it is important to think about factors such as compatibility with the molding process, the preferred visual outcome, and the ecological conditions the item will face. Thermoplastic products like abdominal muscle, polypropylene, and polycarbonate are frequently used for in-mold decors because of their convenience and ability to attain elaborate styles. These products offer excellent moldability, allowing suppliers to create intricate shapes and patterns with precision.

Furthermore, the chosen material needs to have great attachment homes to guarantee that the decor sticks securely to the substratum during the molding procedure. Attachment between the decor and the material is crucial for protecting against delamination and making sure durable visual charm. Furthermore, products with high heat resistance are liked for in-mold decors, specifically for products that will certainly be subjected to raised temperatures throughout their lifecycle. By thoroughly choosing the suitable material for in-mold designs, makers can enhance the general top quality and toughness of their items, satisfying the assumptions of both clients and end-users.

Layout Advancement

A necessary aspect in progressing the field of in-mold decors is the constant expedition and application of layout development techniques. Design technology plays an important function in boosting the visual allure, performance, and general high quality of products made utilizing in-mold design processes. By incorporating innovative layout components, makers can distinguish their products on the market, draw in customers, and stay ahead of competitors.

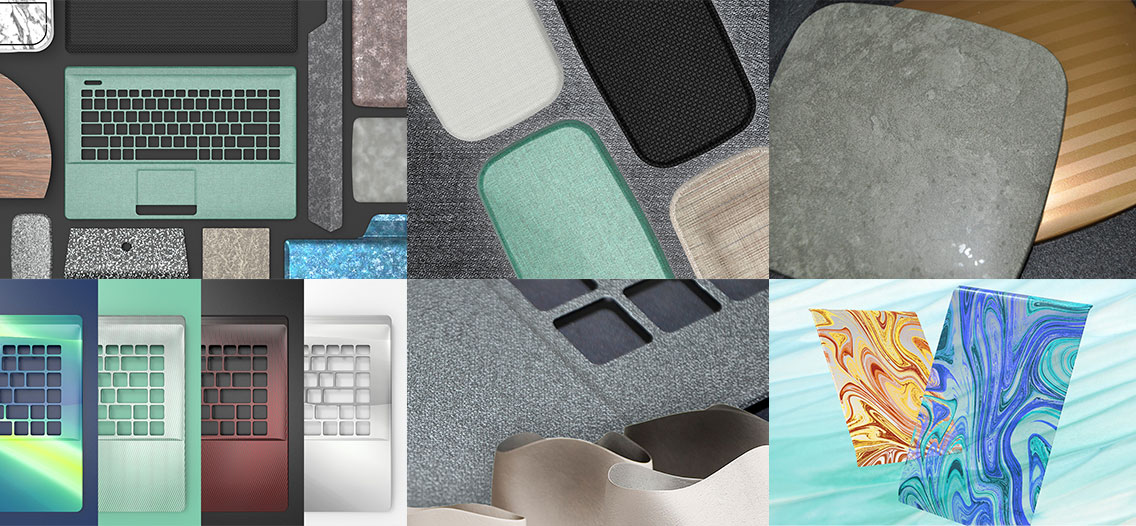

One of the key aspects of design development in in-mold decorations is the combination of intricate patterns, structures, and graphics that were formerly challenging to accomplish with traditional decoration approaches. Advanced modern technologies such as 3D printing and electronic design tools enable designers to develop complex and in-depth designs that can be effortlessly moved onto shaped components. Furthermore, making use of vibrant colors, metal surfaces, and unique impacts like gloss or matte textures can additionally elevate the visual allure of in-mold enhanced items.

In addition, style development extends beyond visual appeals to include practical enhancements such as ergonomic forms, integrated features, and adjustable components that satisfy particular customer requirements. By embracing layout advancement, suppliers can open brand-new possibilities for product, customization, and creativity distinction in the competitive landscape of in-mold decorations.

Manufacturing Performance

Efficient production procedures are crucial for translating the innovative layouts established in the area of in-mold decorations right into premium completed items that meet market demands and consumer expectations. In the world of in-mold decorations, production efficiency incorporates different crucial elements that contribute to the total success of the production process.

Additionally, implementing automation and robotics in the assembly line can significantly boost effectiveness by streamlining recurring tasks and decreasing the margin of error. Automation not just increases the manufacturing procedure however likewise improves accuracy and repeatability, leading to a much more premium More Info and uniform final result. Adopting lean manufacturing concepts, such as just-in-time supply administration and waste reduction strategies, can better boost production effectiveness by minimizing downtime and optimizing resource application. On the whole, an all natural approach to manufacturing effectiveness is paramount in making the most of the capacity of in-mold decor techniques and attaining optimal cause the competitive market landscape.

Quality Assurance Measures

What are the crucial techniques for making sure rigid quality control actions in the world of in-mold decors? Quality control actions are vital in in-mold decoration processes to make certain the manufacturing of perfect and high-quality ended up items. One crucial strategy is the implementation of rigorous evaluation protocols at every stage of the production procedure. This includes performing comprehensive visual inspections, dimensional checks, and shade consistency evaluations to recognize any problems or inconsistencies early on.

Using sophisticated innovations such as automated examination systems can also improve the top quality control procedure by giving exact and reliable information for analysis. These systems can find flaws that may be missed by hand-operated inspections, thereby improving overall item top quality and consistency.

Routine training and advancement programs for workers associated with the in-mold design procedure can additionally add to keeping top notch standards. By educating staff on finest practices, top quality assumptions, and the relevance of interest to information, firms can foster a culture of top quality awareness throughout the company.

Consumer Charm

To boost the bankability of find this in-mold decor items, understanding and providing to consumer preferences play a crucial function in determining their allure and success. Using customization alternatives such as personalized styles, shade variations, and textural components can substantially boost the appeal of in-mold decoration products.

Conclusion

In-mold decors supply a versatile and effective means to improve product appearances. Grasping in-mold decorations needs an alternative technique that thinks about all aspects of the production process to guarantee success.

In the realm of manufacturing, the art of in-mold decorations stands as an essential aspect of product style and production. Design development plays an essential role in enhancing the visual charm, capability, and total quality of items produced utilizing in-mold decor processes.One of the vital facets of design innovation in in-mold decorations is the assimilation of detailed patterns, appearances, and graphics that were previously testing to achieve with typical decor methods.Efficient production procedures are necessary for converting the innovative designs created in the field of in-mold decorations right into top quality ended up products that fulfill market needs and customer assumptions. Supplying modification choices such as individualized layouts, color variations, and textural elements can considerably enhance the allure of in-mold design items.

Report this page